New Installations

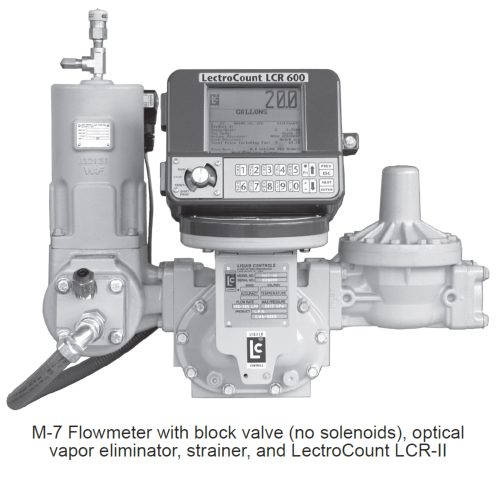

When ordered with a new meter, a A2800 Series solenoid operated block valve is mounted to the meter at the factory. The valve solenoids are prewired to the LectroCount electronic register and optical or vapor eliminators (if included in system) at the factory. Connect the system piping to the 2-inch NPT flange on the outlet side of the block valve.

Retrofit Installations

Depending on the existing configuration, adding a block valve may require modification of the outlet piping. After the internal pressure is relieved from the system, the outlet line can be disconnected from the mechanical valve being replaced. The new valve assembly can then be connected to the outlet side of the positive displacement meter. Use the four bolts and washers to fasten the valve assembly to the meter. The valve has an arrow showing the direction of flow. Ensure that the valve is properly oriented. Tighten the bolts in a crossing pattern. Once this is complete, the outlet piping may be reconnected to the outlet side of the differential preset valve. The valve outlet fitting is 2-inch NPT.

|

SOLENOID WARNING - ALL MODELSFor all models of block valves, the earth-ground to the green screw on the solenoid terminal block is not essential for the operation of the device. In a truck application, the solenoid automatically grounds to the truck chassis through the liquid-carrying piping. Check any applicable electrical codes to comply with proper grounding procedures. |

A2843 Valve - Single-stage LPG Applications

A2859-11 Valve - Two-stage LPG Applications

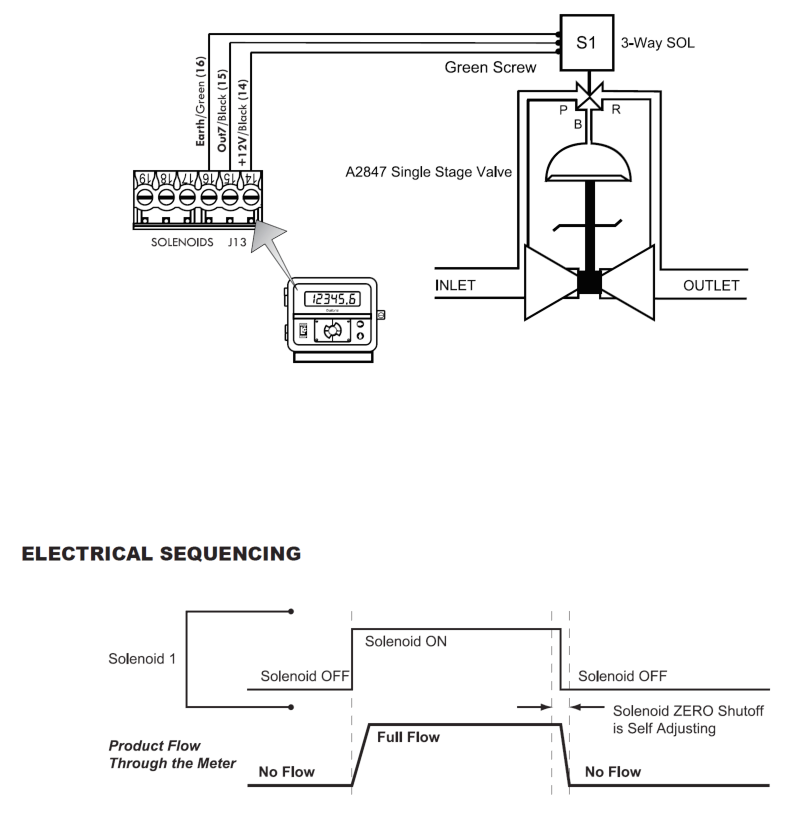

A2847-11 Valve - Single-stage, Refined-fuel Applications

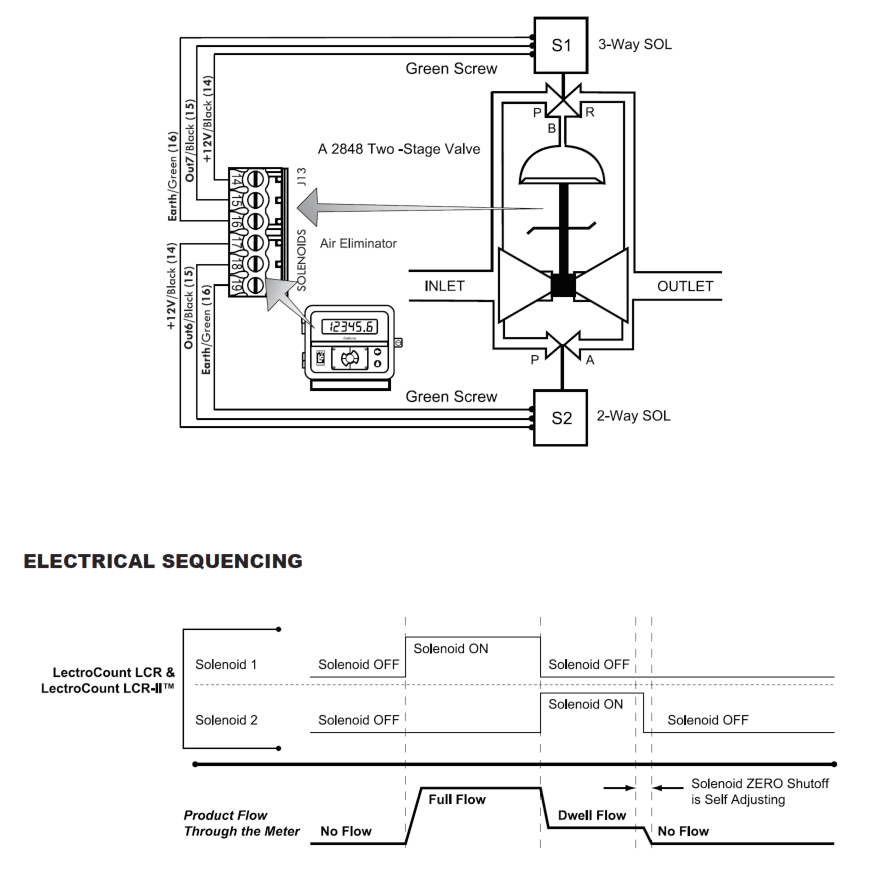

A2848-11 Valves - Two-Stage Refined Fuel Applications